Announcements

Drinks

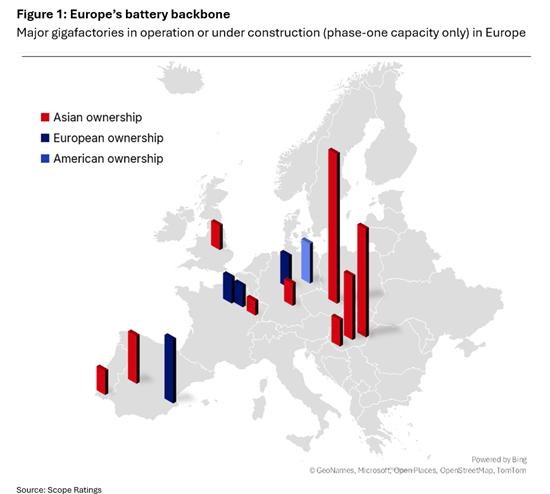

Europe’s gigafactories: kick-starting sector requires delicate industrial, financial trade-offs

As the collapse of Sweden-based Northvolt showed, investors in gigafactories, as large-scale battery-making facilities are known, are confronted with significant sector-specific challenges, from the complexity of achieving steady-state production amid uncertain demand for EVs and specific battery types to China’s control over important links in the supply chain, Scope says in research published today: High-voltage venture: financing Europe’s gigafactory ambitions

“The complex ramp-up process for a new gigafactory with no track record makes it unlikely that any project funded with non-recourse debt will secure an investment-grade rating during the construction phase,” says Marton Zempleni, analyst in Project Finance ratings at Scope.

“While lenders’ risks can be mitigated through suitably adapted financing strategies and structures to create a bankable transaction, kick-starting the European sector involves delicate trade-offs,” Zempleni says.

Focusing on a single product can help manage the complexity of ramping up battery production, but it may weaken the project’s long-term economic fundamentals given the uncertainty over how EV-related technology is evolving. Then again, Northvolt’s product diversification created extra complexity that helped undermine its business.

Purchase commitments from auto manufactures are crucial

Financial backers also need to recognise the lack of clarity over the long-term outlook for specific battery chemistries and higher production costs of European than Asian players. As a result, securing long-term orders through offtake commitments from the automotive sector’s original equipment manufacturers (OEMs) is crucial, especially for raising non-recourse financing.

Even then, anyone financing nominally independent European gigafactories – with EUR 7bn in projects in construction or ramp up – faces the reality that the supply chain remains deeply reliant on China – e.g., a near monopoly over anode supply – and therefore vulnerable to tensions in US-China-Europe trade relations which have risen sharply since Donald Trump returned to the White House.

Lenders need to prioritise European projects with a clearly defined scope and viable industrial plan supported by long-term stakeholder commitment, while acknowledging that market dominance will remain out of reach for some time.

“In this context, the emergence of the Battery Valley cluster in northern France is an encouraging sign of progress towards a sustainable sector in Europe,” says Zempleni.

European policymakers have become more concerned about the absence of European-controlled gigafactories amid broader efforts to enhance the region’s strategic autonomy, given the strategic importance of car manufacturing to European economies and employment and the significant portion of overall EV costs that batteries represent (up to 40%).

“The reality, however, is that the projects in the pipeline are likely to only partially close this gap,” says Zempleni.

Northvolt’s bankruptcy removed substantial capacity from the European battery pipeline. What is left is ACC – a joint venture of Stellantis NV, Mercedes-Benz AG and TotalEnergies SE – which has postponed gigafactory projects in Germany and Italy, focusing instead on its French site.

Volkswagen AG has two gigafactories under construction, one in Germany and one in Spain, but has reduced the initial capacity of the Salzgitter plant by half. France’s Verkor – backed by Renault SA and financial sponsors – is building a gigafactory in Dunkirk in northern France.